Coir – from Sri Lanka to Peshastin

All of our plants are grown in containers (as opposed to in the ground) so we need growing media (e.g. soilless substrate or potting mix) to grow them in. The properties of that media are crucial to the health and growth of our plants, whether new seedlings in 10 cubic inch tubes or eight-foot trees in 10-gallon pots. Most commercially available mixes have sphagnum peat as their basis. This material works well holding water, nutrients and, equally important, air in the mix, especially when combined with other materials like vermiculite or perlite.

A concern with peat is that it is essentially a non-renewable resource. Most peat in the US comes from drained peat bogs in Canada, where it has slowly formed over centuries. It is harvested far faster than it is created and in the process eliminates carbon sinks, wildlife habitat and water filtration. An alternative I’ve been using the past few years is coir.

Coir (pronounced ‘coy-yer’) is the natural fiber extracted from the husk of the coconut between the hard internal shell and the outer coat. Most of the world’s supply comes from coconut growers in Sri Lanka, India and the Phillipines. The longer fibers are used to make rope, floor mats, brushes and more; the fibers too short for this were considered a waste product. Now, with their use as a peat alternative, they are compressed into large bricks and shipped around the world to be sold as “coco-peat” or “coco-coir”.

Compared with peat, the cost of coir per cubic foot (2013 prices) is the same or slightly less. The bricks expand about 5X in volume when reconstituted. I can pick up a year’s supply from my nursery supplier in Snohomish with one truck trip; the equivalent amount of peat takes three trips with truck and trailer. Coir has more lignin than peat, so takes longer to decompose and maintains soil aeration longer, a critical quality of most native plant soil mixes. The main disadvantage is that it takes time, space, water and a tiller to effectively expand and prepare this product. We use coir in the soil mixes we prepare at up to 40% of the total volume, combining it with varying amounts of bark, a local compost and perlite. We are getting better with its use and will keep at it so long as we have good supervision (see below).

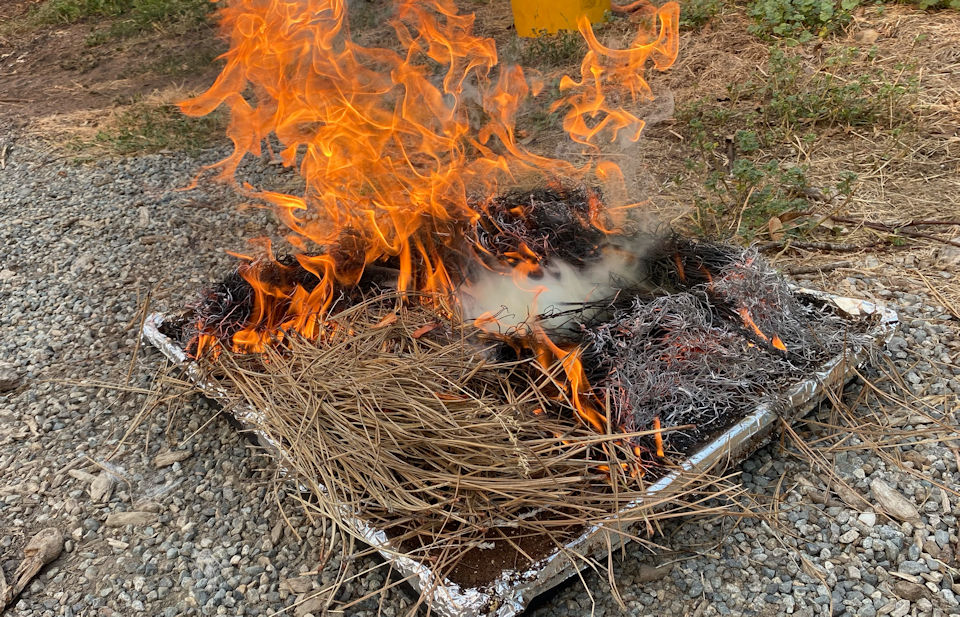

Joey supervises the process

Flaco, working hard as usual